High precision production equipments and inspection equipments from Germany and Japan to ensure tight up to 0.003 tolerance and high quality of metal parts.

Many Fortune 500 companies such as ABB, Schneider, BOSCH, HUAWEI, LEMAN and ALFANAR and so on has been our customers for over 10 years.

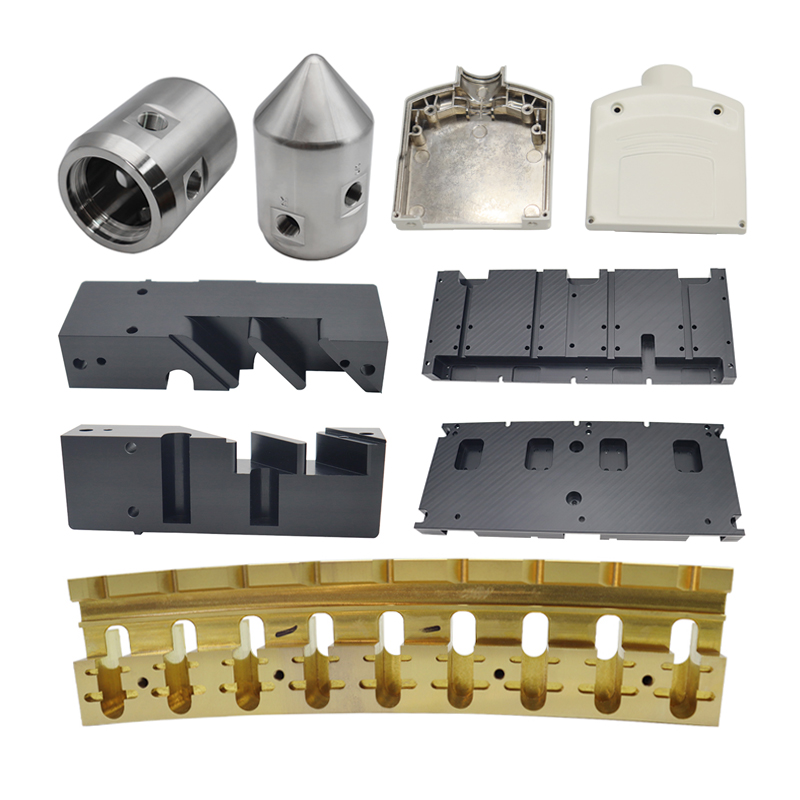

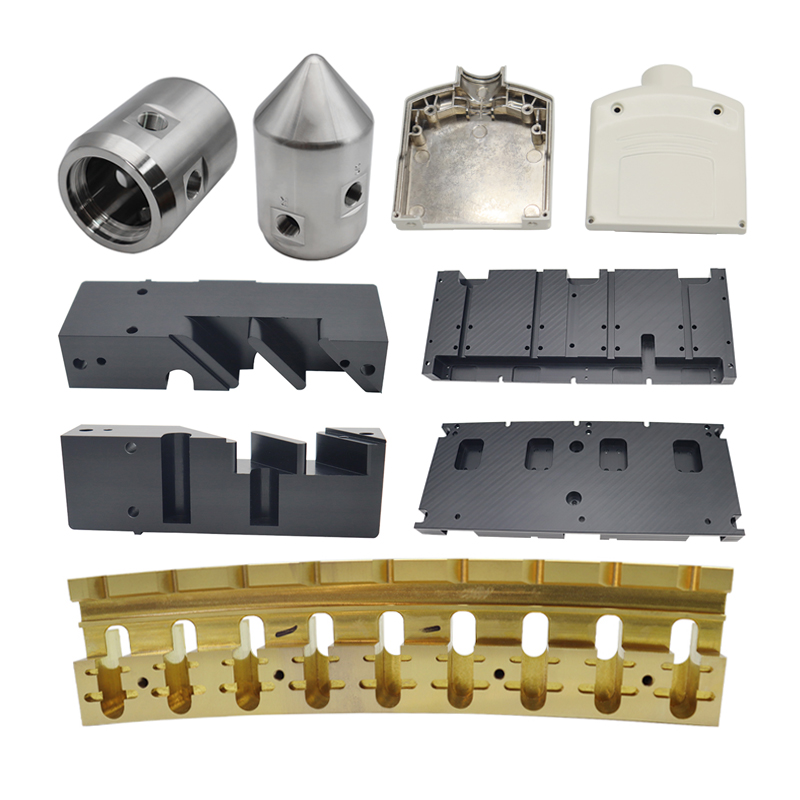

Mulmic Co., Ltd., founded in 2006, is one of leading professional manufacturer of precision metal parts in China, our main products include customized high precision machinery parts, 5-axis CNC machining parts, CNC milling parts, CNC turning parts, precision metal stamping parts and sub-assembly(including welding & riveting).

Our main production equipment and inspection equipment are imported from Germany, Japan and Taiwan, our 5-axis CNC machining center with famous brand of Hermle Germany & Matsuura Japan can ensure much tight tolerance to 0.005mm during manufacturing process...

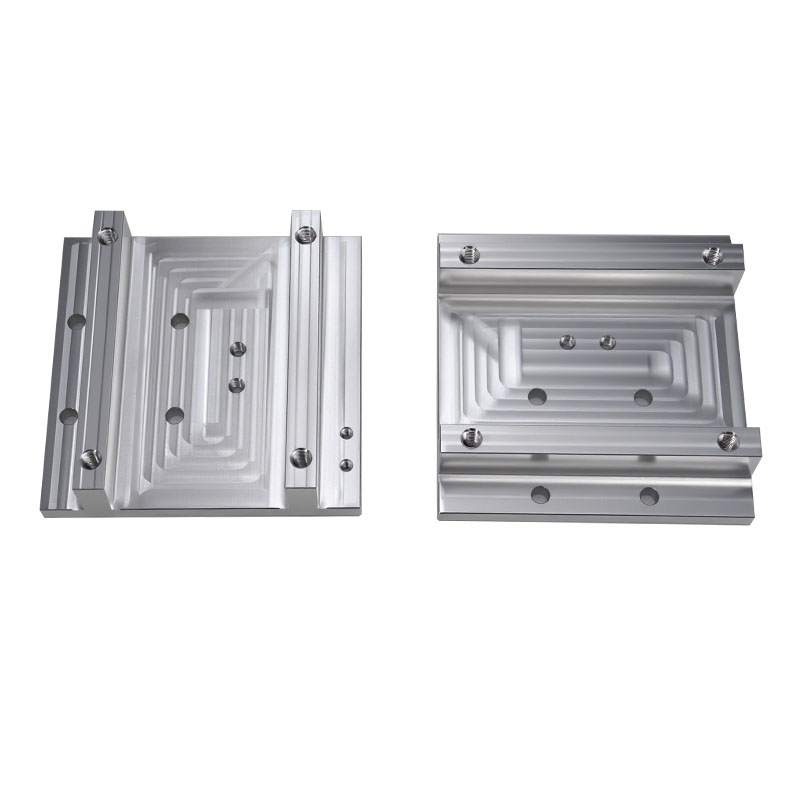

Precision CNC Milling Work Aluminum Parts -

Precision CNC Milling Work Aluminum Parts

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Precision CNC Milling Parts -

Precision CNC Milling Parts

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Aluminum CNC Machined Parts Custom Manufacturer Low Cost Milling Processing Supplier-

Aluminum CNC Machined Parts Custom Manufacturer Low Cost Milling Processing Supplier

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

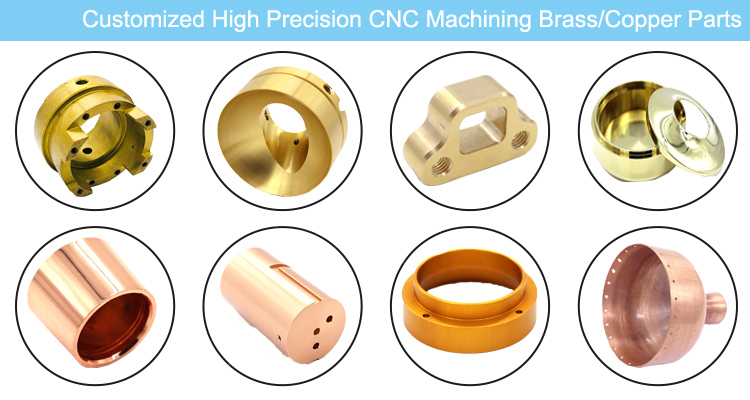

Oem Custom Cnc Turning Service Precision Anodized Aluminum Stainless Steel Brass Titanium Parts Rapid Prototyping-

Oem Custom Cnc Turning Service Precision Anodized Aluminum Stainless Steel Brass Titanium Parts Rapid Prototyping

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret with tooling attached is programmed to move to the bar of raw ...

CNC machined robot parts-

CNC machined robot parts

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Aluminum Manifold-

Aluminum Manifold

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Motorcycle cylinder cover-

Motorcycle cylinder cover

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Motorcycle Engine Part-

Motorcycle Engine Part

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

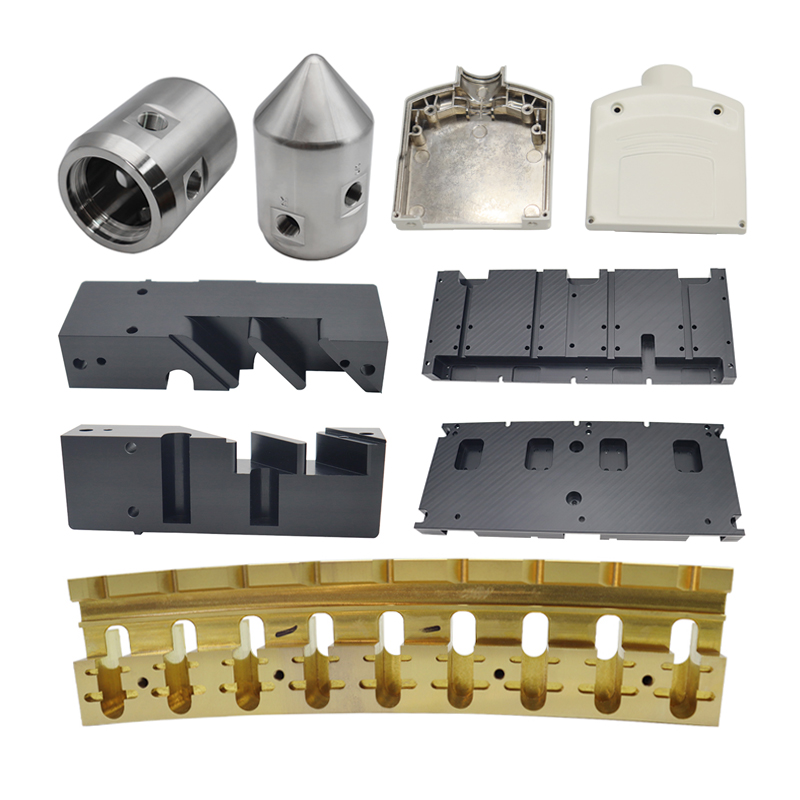

ISO9001 Certified Factory Custom High Precision CNC Machining Stainless Steel Aluminum Copper Titanium Auto Engine Parts-

ISO9001 Certified Factory Custom High Precision CNC Machining Stainless Steel Aluminum Copper Titanium Auto Engine Parts

19+ years Custom Machining Services Professional & specialized 20+ Skilled Machinists Efficient production 3000 + m² Machining Workshop In-house facility/Flexible storage 100% Precision Inspection Quality assurance 10+ Machining Processes Vers...

High Accuracy Cnc Machined Parts Manufacturing Custom Design Metal Steel Titanium Prototype Small Batch Production-

High Accuracy Cnc Machined Parts Manufacturing Custom Design Metal Steel Titanium Prototype Small Batch Production

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret with tooling attached is programmed to move to the bar of raw ...

Professional Precision Cnc Milling Services Metal Components Brass Aluminum Alloy Anodizing Surface Treatment-

Professional Precision Cnc Milling Services Metal Components Brass Aluminum Alloy Anodizing Surface Treatment

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Cnc Parts Auto Spare Aluminum Stainless Steel Turning Machined Custom Precision Prototype Machinery Service-

Cnc Parts Auto Spare Aluminum Stainless Steel Turning Machined Custom Precision Prototype Machinery Service

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret with tooling attached is programmed to move to the bar of raw ...

Stainless Steel Cnc Parts Aluminum Alloy Auto Spare Turning Machined Custom Precision Prototype Service-

Stainless Steel Cnc Parts Aluminum Alloy Auto Spare Turning Machined Custom Precision Prototype Service

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret with tooling attached is programmed to move to the bar of raw ...

OEM ODM Custom Metal CNC Turning Service -

OEM ODM Custom Metal CNC Turning Service

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret with tooling attached is programmed to move to the bar of raw ...

One Stop Custom Precision CNC Milling Aluminum Parts -

One Stop Custom Precision CNC Milling Aluminum Parts

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

OEM Precision CNC Milling Aluminum Parts -

OEM Precision CNC Milling Aluminum Parts

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Precision CNC Milling Aluminum Parts -

Precision CNC Milling Aluminum Parts

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Professional Custom CNC Turning Service -

Professional Custom CNC Turning Service

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret with tooling attached is programmed to move to the bar of raw ...

Professional Custom CNC Turning Service For Stainless Steel Aluminum Brass Titanium Alloy Metal Hardware Fabrication-

Professional Custom CNC Turning Service For Stainless Steel Aluminum Brass Titanium Alloy Metal Hardware Fabrication

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret with tooling attached is programmed to move to the bar of raw ...

Precision CNC Milling Work Aluminum Parts -

Precision CNC Milling Work Aluminum Parts

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Precision CNC Milling Work Aluminum Parts -

Precision CNC Milling Work Aluminum Parts

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Precision CNC Milling Parts -

Precision CNC Milling Parts

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Aluminum CNC Machined Parts Custom Manufacturer Low Cost Milling Processing Supplier-

Aluminum CNC Machined Parts Custom Manufacturer Low Cost Milling Processing Supplier

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Oem Custom Cnc Turning Service Precision Anodized Aluminum Stainless Steel Brass Titanium Parts Rapid Prototyping-

Oem Custom Cnc Turning Service Precision Anodized Aluminum Stainless Steel Brass Titanium Parts Rapid Prototyping

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret with tooling attached is programmed to move to the bar of raw ...

CNC machined robot parts-

CNC machined robot parts

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Aluminum Manifold-

Aluminum Manifold

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Motorcycle cylinder cover-

Motorcycle cylinder cover

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Motorcycle Engine Part-

Motorcycle Engine Part

CNC milling is a part fabrication technique carried out with the aid of a high-speed automatic cutting machine designed to remove unwanted material from a part. CNC mills are available in various sizes, capacities and axial configurations. They can ...

Hi.Chloe

I've received the CNC machined parts. They're a perfect fit and I couldn't be happier. Thank you very much for all your help. It's been a true pleasure to do business with you and I know who I will contact if l need some special manufacturing later. I will recommend you to all my business partners.Thanks again!

Kind regards, Woje

Customer from Australia